COVID-19 Shocks Food Supply Chain, Spurs Creativity and Search for Resiliency

The global food supply chain has been rocked by the pandemic, leading to disruptions and shortages and adding to the problem of waste. There's also the human cost, such as the economic harm to the laborers whose jobs or hours are cut and the growing problem of food insecurity for millions. Still, there are signs of hope, such as the success of smaller grocers in maintaining supply lines with local sources.

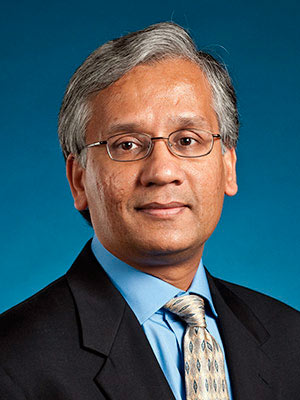

Ravi Anupindi is a Ross School of Business professor and founding faculty director of the Center for Value Chain Innovation. His interests include sustainability and food systems. He has written a case study on Michigan Dining, which provides food in all the U-M dorms, and their quest to go 20 percent local. The case highlights some of the challenges faced by large institutional buyers (like MDining) to buy local. He also serves as a board member of the Fair Labor Association and is a member of its Agricultural Committee that develops principles and guidance to ensure labor standards and human rights in global agricultural supply chains.

Anupindi discusses the many challenges—and some opportunities—for the players in the food supply chain as it deals with the fallout from COVID-19.

We've seen smaller grocery stores pick up where large chain grocers have failed by supplying pantry staples. What are some of the advantages of being small during a pandemic?

Anupindi: For local suppliers, it is easier to access small stores than large chains as a sales channel. Small stores don't have a large bureaucracy or systems to onboard suppliers. A Kroger or Walmart cannot sign up overnight with a local supplier — corporate will have to approve it, for instance. Small producers have lost their usual channels of sales, such as farmers' markets, so they need an outlet. Produce has its own cycle and needs to be harvested and sold, otherwise they go to waste, so suppliers have an urgency to sell. That means they're eager to find these sales channels.

Obviously, these smaller operators cannot supply everything for their communities, but what can the larger chains learn from them in terms of supply chain management?

Anupindi: I am not certain that there are big lessons to learn from smaller operators. The larger point may be to build resilience. One way to do this is to diversify sources to include local suppliers. So when their national supply gets disrupted, the local supply line is still open. Up until now, going "local" was labeled as a more sustainable option and often demanded premium prices, so only certain types of stores had local foods. But one could also view local sourcing as a resiliency strategy.

How are large grocery store chains supply chains hobbled during a pandemic in unanticipated ways?

Anupindi: COVID-19 has created multiple shocks to these supply chains. These can be divided into demand and supply shocks.

On the demand side, sales to restaurants, food services and institutions such as universities, has mostly tanked. There is some take-out business from restaurants but not enough. Food consumption has shifted to homes, where consumers buy from grocery stores. For example, 52 percent of all the fruits and vegetables in the U.S. are sold through the food service sector, which is almost shut down. Even if the same ingredients were used in both channels, the way they are packaged, moved through the supply chain and bought is different. For example, restaurants and institutions will take bulk packaging not suitable for home channel consumption. Meats supplied to restaurants and hotels are often cut and packaged differently than those sold in grocery stores.

In addition, the types of items bought in these two channels may vary as well. Upper-end restaurants may buy high-value products that are more difficult to sell in a regular grocery channel. After all, when we go out for a meal we would like to eat something special that we may not be able or willing to cook at home.

Buying more often is not a great option now, given an imperative to limit contact with other people, leading to buying more but less frequently. Hoarding behavior of consumers, especially seeing empty shelves, creates a demand shock in the supply chain that was designed for a smoother flow of products in a more or less just-in-time fashion. With rising prices of products due to shortages and the real or potential loss of incomes for many consumers they may get more conservative with their food bills and alter their choices as well. Limited storage space at home may also mean a shift to buying fewer perishables. Another shift may be buying online. Overall, these factors impact demand in terms of volume, size, frequency and variety.

On the supply side, there are multiple shocks all along the chain, from producers and processors to logistics and distribution. Labor shortages plague the producers. Laborers may be hesitant to come to work and even when they come, it can be hard to maintain social distance in farms. Maintaining social distance also means lower productivity in certain activities, such as picking strawberries.

With travel restrictions, especially across southern borders, availability of labor is becoming a problem. Similarly, processing plants are not structured to maintain social distance among workers. There have already been factories with higher infection rates. Food distributors and wholesalers in the middle of that supply chain have to redirect truckloads of food from shuttered businesses toward places where people now crave it — mainly grocery stores. For imported foods, border closures and reduced airline capacity is impacting supply. As consumer traffic for food purchasing moves to grocery stores, they, too, are facing short supply of labor.

There are stories about massive food waste as suppliers have nowhere to store produce and dairy that the restaurant industry no longer needs. How does something like this happen? What's wrong with the way we get these products to market that gets exacerbated during the pandemic?

Anupindi: Some of this is because of shifting channels of sales. Take milk. A large fraction of it goes to schools in single-serve packaging. Milk is also consumed in bulk at restaurants for food preparation. With schools and restaurants closed, some of that sales moves to grocery stores but then manufacturers have to adjust their packaging appropriate for grocery store sales. Also, kids may not fully consume milk in single-serve cartons in schools but at home there will be less waste, which means overall milk consumption comes down. Similarly, the bulk movements of produce and fresh items to restaurants need to be adjusted to appropriate size packaging to move through grocery stores. While these adjustments that take time and consumption drops, food perishes.

With transport links under strain, producers are unable to move as much product to markets. With labor shortages, harvesting productivity goes down, so food rots in the field. However, local farms can try and adjust to sell directly or through smaller local stores.

Short of wasting all this food, isn't the food industry set up to donate products to food banks or large school systems feeding their communities? How could the supply chain be altered to make the industry more sustainable?

Anupindi: Yes, some of this is happening. But again, this requires a different distribution capacity and takes time to adjust to. Food waste has been a big problem in the U.S. food system with many causes. According to a study by the Food and Agriculture Organization of the United Nations, globally around one-third of all food produced is lost or wasted along the food chain from production to consumption. This is exacerbated in the pandemic. Our food system travels long distances, on average 1,200-1,500 miles, to get to the plate. It's a complex problem that requires creative solutions from productivity, ecosystem diversity, supply chain, technology and consumer behavior issues.

Do you think the increased business flooding to smaller stores will evaporate once the coronavirus is behind us?

Anupindi: Most likely, a majority of it will. When supply chains swing back to normal, larger chains will compete better on price and availability. Prices are likely higher in smaller stores so with incomes impacted, consumers will look for cheaper options and go back to larger chains. Some consumers may like the freshness of products in smaller stores, assuming these come from local farms, and continue to purchase there. This, too, is uncertain as farmers markets may open up and demand could shift back to these outlets.

What else is important to understand or know about the food supply chain during these times?

Anupindi: We have many vulnerable, food insecure populations, including roughly 11 million children, about a third of undergraduate students, the elderly and low-income families. Their access to food is significantly impacted by the pandemic.

Ravi Anupindi is the Colonel William G. and Ann C. Svetlich Professor of Operations Research and Management, professor of technology & operations, and faculty director of the Center for Value Chain Innovation at the University of Michigan Ross School of Business.

Media contact: Jeff Karoub jkaroub@umich.edu